Screen technology does not stand still. In recent years we have seen steady improvements in OLED and LCD but there is also a new technology to come. We tell you all about microLED: what is it, what can you expect from it and which hurdle must the technology still overcome before we will see it?

What is a microLED?

A LED (Light Emitting Diode) knows in the meantime everyone. The small semiconductor component has found its way into virtually all consumer electronics. The use is no longer limited to the tiny indicator lights, LEDs are used as background lighting in television and monitors, and in all kinds of lighting applications. You pimp your computer case with it, and in the living room compact and economical LED versions replace the halogen lamps and other energy saving lamps. The flash of your smartphone is an LED, just like some photography lamps, and even worklights are using LEDs in the meantime.

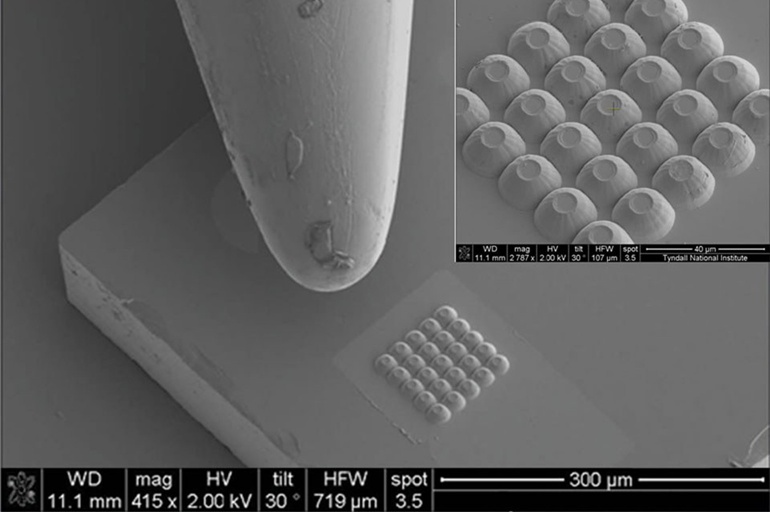

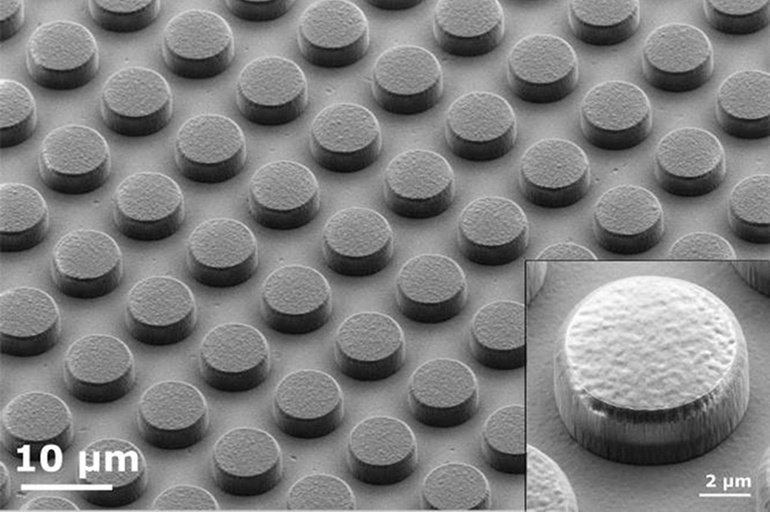

But it is not only being researched how we can make LEDs bigger and more powerful. Because it is a semiconductor component, it can be made very small like other components. We define a microLED as LEDs smaller than 100 micrometers (0.1mm). However, this is not a hard definition; you will also find larger microLEDs, and the smallest ones are barely a few micrometers.

An array of 25 microLEDs, next to the tip of a needle. (InfiniLed)

(Leti)

What is a microLED screen?

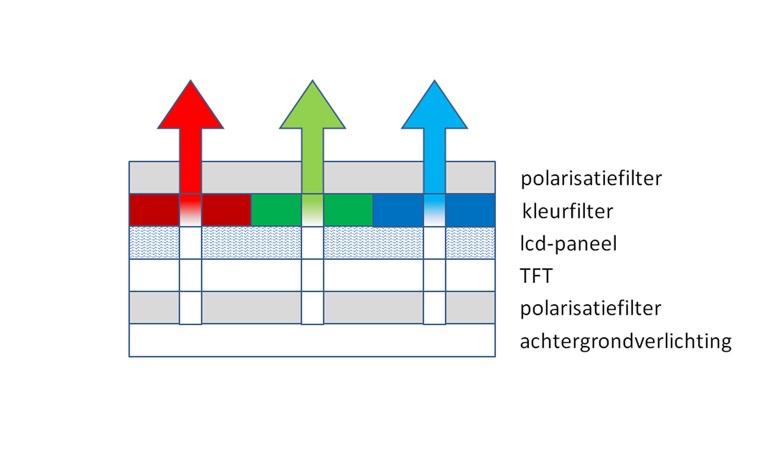

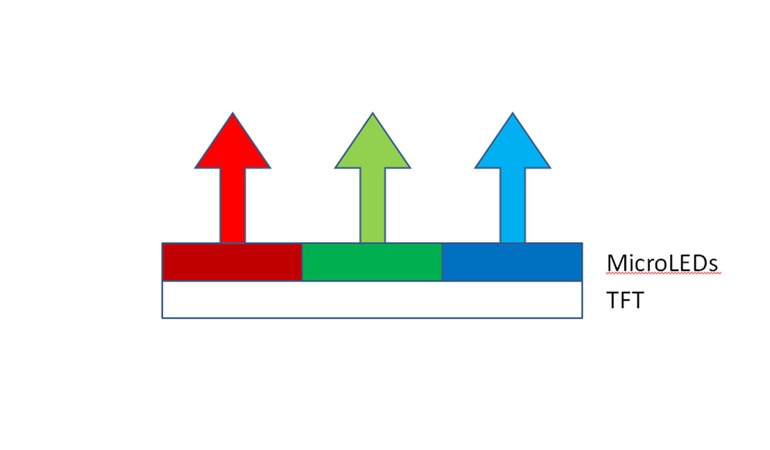

Very small LEDs, how do you make a screen with them? The concept is very simple. Each pixel on a screen contains a red, green and blue subpixel. A microLED screen uses a separate microLED for each of those subpixels. For comparison we first give the structure of an LCD screen. There, a backlight for the light, and the LCD layer controlled by tft (thin film transistors), together with the polarizers, provides individual pixels.

With a microLED screen, that structure sees a lot easier. Each sub pixel is a microLED that is controlled directly by the tfts. Each (sub) pixel gives itself light and can be perfectly switched on or off.

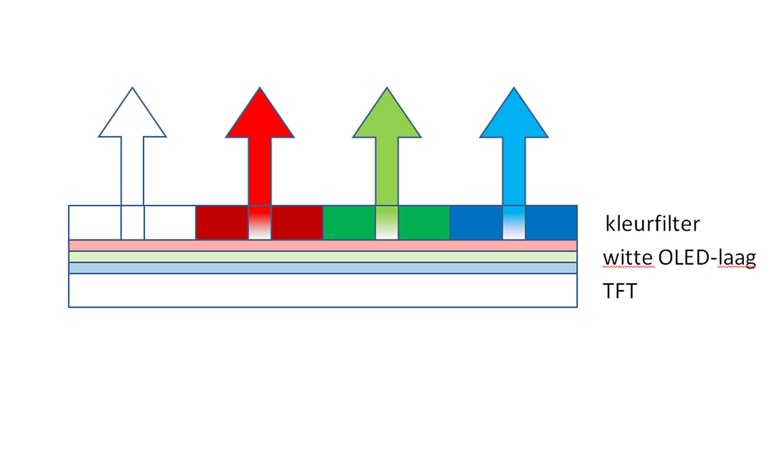

This structure is very similar to that of OLED, by the way. RGB OLED screens (such as those in a smartphone) are constructed in the same way. That of the current OLED televisions is slightly different, we also give them for completeness. Instead of red, green and blue sub pixels, they all use white sub pixels, which are combined with a color filter. In addition, these OLED screens also use a white subpixel (which is why we also call it WOLED).

Advantages of a microLED screen

We do not just make that comparison with OLED. As with OLED, each subpixel of a microLED screen provides light itself. That means that, just as with OLED, you speak of an emissive screen with perfect black value, excellent contrast and a very wide viewing angle. The response time is also excellent, probably even better than that of OLED. That could provide even better sharpening (although reaction time is not a cure for motion sharpness ). Also in terms of color range microLED screens can perform very well, although there are still some hurdles to overcome.

The main advantage of a microLED screen is the high energy efficiency and the higher luminance (simply put: brightness). LEDs are extremely energy efficient (100-150 lumen / watt is no exception, compare with 10 lumen / watt for a conventional light bulb and 20 lumen / Watt for a halogen) and microLEDs could possibly be even more efficient. InfiniLED, a microLED manufacturer that was taken over by Oculus, claims a reduction in consumption from 20 times to 40 times, but does not indicate what other screen technology it is. The higher luminance would then be a huge advantage for HDR playback (or for our smartphones if we use them outside). Finally, the lifespan of microLED screens would also be excellent.

In short, microLED combines many advantages of both LCD and OLED and adds a number of additional improvements to it.

Manufacturing hordes

If the technology is so great, why do not we use them yet? One of the first hurdles is finding a good solution for color rendering. The most efficient LEDs give blue light. To make colored LEDs, phosphors are used in traditional LEDs. But phosphor particles are unfortunately larger than the smallest microLED and therefore can not always be used. It is therefore necessary to look at other materials (new type of nitride LEDs and quantum dots) to solve them.

The biggest hurdle for manufacturing, however, is the transfer from the microLEDs to the screen. A microLED, like another semiconductor component, is grown on a substrate. That should then be cut, and then you have to record the tiny microLEDs and move them to the screen. This mass transfer must then also be done with enormous precision, reliability and speed. Of course, an enormous amount of research is being done here.

An example: the Korea Institute of Machinery & Materials (KIMM) has developed a rolling process for this. In a first step, the TFT layer is rolled on a temporary glass plate, then the microLEDs are picked up and rolled onto the TFT layer. Finally, the resulting AMOLED layer (active matrix LED) can be brought from the temporary glass to a rubber underlayer. This is how you make a stretchable and foldable screen.

How far we stand for commercialization is hard to say. PlayNitride (a microLED manufacturer that Samsung wanted to take over last year) claims to have a 99% reliability in its labs for mass transfer. In a lab setup it takes about 10 seconds to transfer 200,000 microLEDs. That seems quick, but keep in mind that you need 6.22 million LEDs for a Full HD panel, and 24,88 million for an Ultra HD panel.

The price would also be a major obstacle for the time being. LG showed in advance alone the price of the LEDs in an Ultra HD panel can reach up to about 25,000 euros. And that brings us to the next topic.

Where will we see microLED screens?

MicroLEDs are better than OLED in lifetime and better than LCD in panel thickness. It is better than both in response time, and delivers perfect black, high light output and is energy efficient. But the price is an obstacle for now, although it depends on the size of the screen.

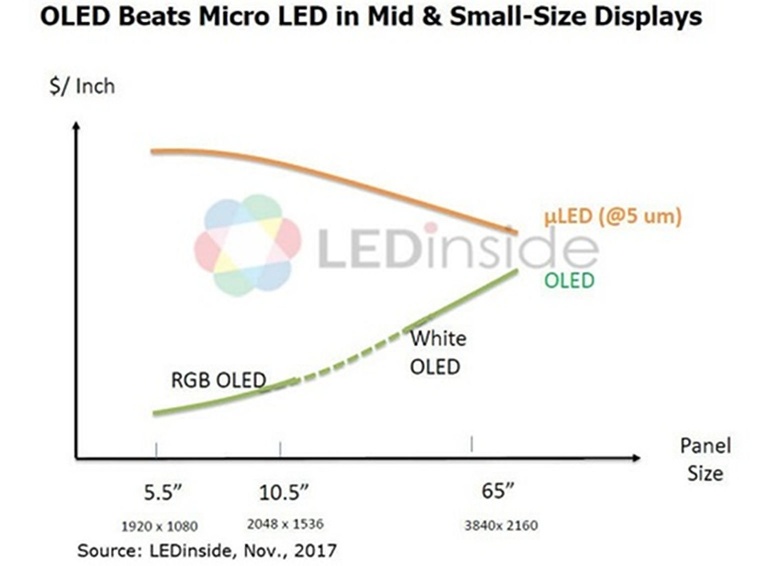

With very small displays, microLED could be an interesting option. Then we think of smartwatches (for example, Apple has taken over LuxVue), but also the screens in VR glasses (Oculus is active in this segment, through the acquisition of InfiniLED), or small HUDs in the automotive sector. For smartphone and television, the price would for the time being exclude the choice for microLED, as you can see on this graph from LEDInside.

It is only at very large screens (100-inch diagonal and more) that microLED back becomes an option. In addition, larger microLEDs are used (300 times 100 micrometers), which are put into modules, so that you can build different screen sizes (with different resolutions). The 146 inch microLED screen that Samsung introduced at CES works like this, and these modules from LUMENS admit the same principle.

Sony also has such a solution, under the name CLEDIS (Crystal LED Integrated Structure). Sony’s demo screen was 9.75 by 2.74 meters and used a resolution of 8,000 by 2,000 pixels, and a maximum brightness of 1,000 cd / m². It is therefore clearly intended for B2B applications. Maybe the name Crystal LED sounds familiar to you? Sony already showed a prototype TV at CES 2012 with this technology, then a 55 “Full HD model.

Intermediate solution: miniLED

For televisions, microLED does not seem to be a solution that we can expect immediately. But there is another possibility. MiniLEDs that are somewhere between a standard LED and microLED would be a good choice to make better backlighting for television, laptops, tablets and smartphones. Typical backlighting today uses a few dozen LEDs.

With miniLEDs, backlighting of several thousand LEDs would be possible. AUO, a well-known panel manufacturer, talks about 6-7,000 LEDs for a notebook panel. TV panels could use up to 10,000 LEDs and more. That creates enormous possibilities for very fine Full Array Local Dimming – background lights, which will provide better black, contrast and HDR reproduction. The best local dimming TVs (like the Sony ZD9) currently use somewhere around 600-700 zones. Mini LEDs would therefore mean a major upgrade. We suspect that the newly announced Samsung Q9S makes use of such a solution.

Conclusion

MicroLEDs offer enormous perspectives as screen technology. They combine the advantages of OLED and LCD: emissive screen, perfect black, high light output, high contrast, wide viewing angle, fast reaction time, good color rendering, long life, energy efficient. But they are really only at the beginning of their introduction. The manufacturing process is for the time being the most important hurdle. In very small screens (wearables) and very large screens (larger than 100-inch) we will probably see the first applications, but for television and smartphones the price is far too high for now.

Add Comment